PPE (Personal Protective Equipment) is the last line of defense for workers against workplace hazards. It refers to equipment worn to mitigate physical, chemical, biological, and other forms of harm, covering multi-part protection such as head protection (e.g., hard hats), eye protection (e.g., safety goggles), torso protection (e.g., protective clothing), and respiratory protection (e.g., face masks). Its core purpose is to "targeted hazard mitigation" rather than replacing safety management measures.

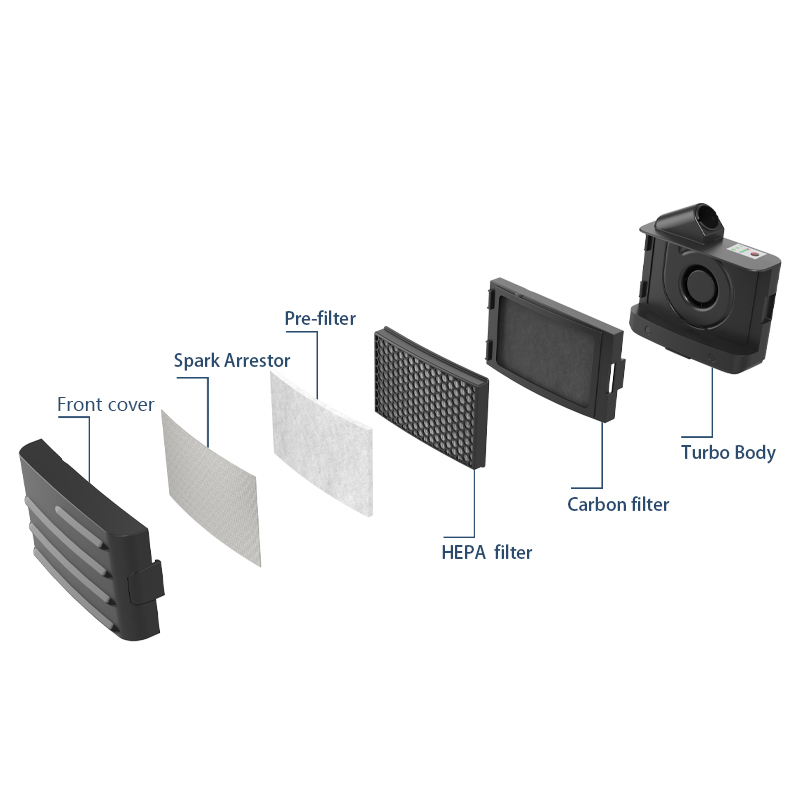

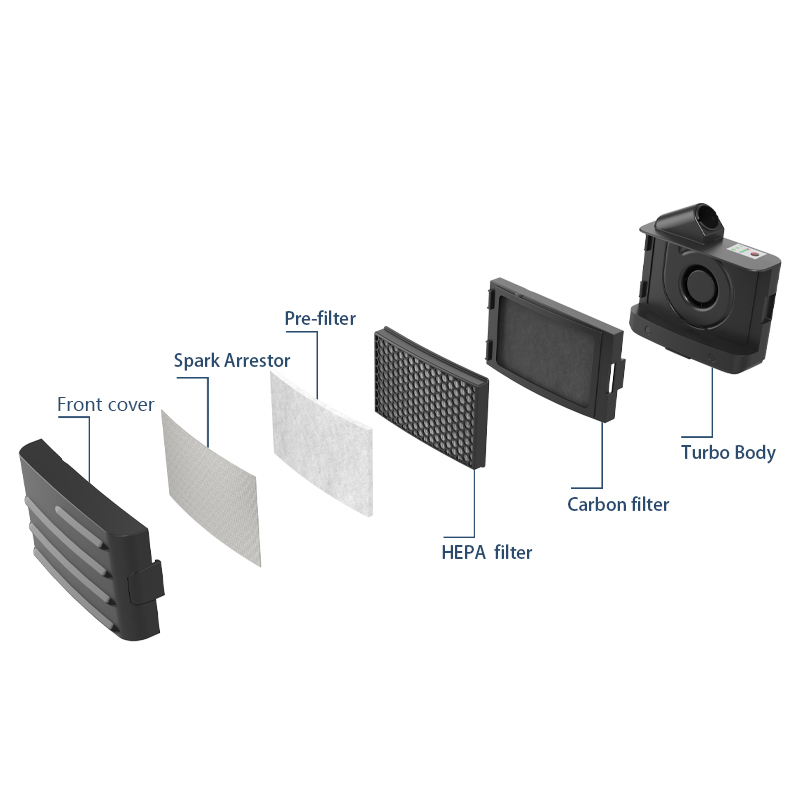

Among various types of PPE, respiratory protection equipment directly safeguards a critical aspect of life. Ordinary dust/mist masks rely on proper fit to function, but in high-risk scenarios, powered air respirator emerges as a more reliable option. Unlike traditional face masks, it is an active protection system composed of an "air supply unit, filter component, and face shield/hood" — the air supply unit generates positive-pressure airflow via a motor, which, after passing through the filter to remove hazardous substances, is continuously delivered into the face shield. This design not only prevents the intrusion of external contaminants but also reduces breathing resistance for the wearer.

The core advantage of papr air purifier lies in its "dual benefits of high protection + comfort". Compared to ordinary face masks, it can filter higher concentrations of dust, toxic gases, or bioaerosols. Additionally, its positive-pressure design avoids reduced face shield fit caused by the wearer's inhalation. Meanwhile, the continuous airflow minimizes stuffiness, making it suitable for long-duration tasks (e.g., chemical maintenance, high-risk epidemic care). It is particularly ideal for individuals with facial hair who cannot wear ordinary face masks properly.

However, the use of air papr must comply with professional standards — a requirement common to all PPE management. Firstly, it is essential to select filter materials (e.g., organic vapor filter cartridges, particulate filter cotton) that match the workplace hazards. Secondly, regular checks of the air supply unit's battery level and filter life are necessary to prevent equipment failure. Before use, a "positive pressure test" should be conducted to ensure no leaks in the face shield — these steps align with the logic of impact testing for hard hats and pressure resistance checks for insulated shoes, all of which are critical to ensuring PPE effectiveness.

Overall, PAPR is a typical representative of "specialized protection" in the PPE system. Its introduction fills the gap left by ordinary respiratory protection equipment in high-risk scenarios. Nevertheless, whether choosing PAPR or basic PPE, the core principle remains unchanged: first, identify hazards through risk assessment, then select appropriate protective equipment, and finally implement usage and maintenance procedures — only in this way can PPE truly serve as the "safety armor" for workers.If you want knon more, please click www.newairsafety.com.