Dec 11, 2025

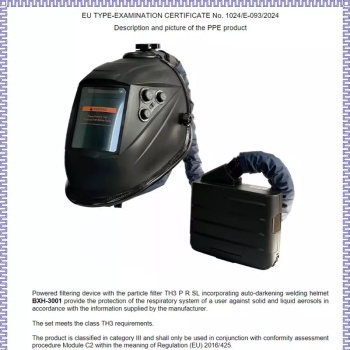

Automotive spraying is a task that imposes dual strict requirements on both process precision and practitioners' health. It not only needs to ensure a smooth, even paint finish with consistent color but also has to deal with various harmful substances pervading the operation. During the spraying process from primer, base coat to clear coat, hazardous materials like paint mist particles, organic vapors and Volatile Organic Compounds (VOCs) are everywhere. Ordinary dust masks or half-masks can barely provide comprehensive protection; what's worse, their high breathing resistance may affect operational stability. As professional protective equipment,air powered face mask (PAPR) has become a "standard protective barrier" in automotive spraying scenarios, thanks to its dual advantages of active air supply and high-efficiency filtration. Today, we'll explore the core reasons why PAPR is a must for automotive spraying and how to select the right model for the scenario.

The particularity of the automotive spraying environment determines that ordinary protective equipment is far from meeting the demands—and this is exactly the core value of PAPR. Firstly, the spraying process produces paint mist particles with a diameter of only 0.1-10 microns. Such fine particles can easily penetrate ordinary masks, and long-term inhalation will deposit in the lungs, leading to occupational diseases like pneumoconiosis. Meanwhile, solvents in the paint (such as toluene and xylene) will volatilize into high-concentration organic vapors. Ordinary activated carbon masks have limited adsorption capacity and will become saturated and ineffective in a short time. Secondly, automotive spraying often requires complex postures like bending over and leaning sideways for long periods. The breathing resistance of ordinary masks increases as usage time goes on, making operators breathe laboriously and lose concentration, which in turn affects the precision of the paint finish. Positive Pressure Air Purifying Respirator With Hard Hat actively delivers clean air through an electric fan, which not only has almost zero breathing resistance but also can block over 99.97% of fine particles and harmful vapors via high-efficiency filtration components, balancing protection and operational comfort.

Besides basic protection, PAPR can also indirectly improve the process quality of automotive spraying—which is another key reason for it becoming an industry necessity. If ordinary protective equipment has poor airtightness, external dust will enter the gap between the mask and the face. Such dust adheres to the undried paint surface, forming "dust spots" and increasing rework costs. However, PAPR masks are mostly designed as full-face or half-face masks, and the elastic sealing ring ensures a tight fit with the face, effectively preventing external pollutants from entering. More importantly, PAPR's active air supply system creates a slight positive pressure environment inside the mask. Even if there's a tiny gap in the mask, clean air will flow outward instead of external pollutants seeping inward. This fundamentally avoids dust defects on the paint surface, which is particularly crucial for fine spraying of high-end automobiles.

Choosing the right Electric Air Supply Respirator model is a prerequisite for exerting protective effects. For automotive spraying scenarios, two core indicators—"filter component type" and "air supply mode"—should be the focus. In terms of filtration needs, the main pollutants in automotive spraying are composite pollutants of organic vapors and paint mist particles. Therefore, a combined filtration system of "organic vapor cartridge + HEPA high-efficiency filter cotton" must be selected: the cartridge can absorb organic solvent vapors like toluene and ethyl acetate, while the HEPA filter cotton blocks fine paint mist particles. The combination of the two achieves comprehensive filtration. In terms of air supply mode, it's recommended to prioritize "portable battery-powered PAPR". It's lightweight (usually 2-3 kg) and has a battery life of 8-12 hours, which can meet the demand for continuous spraying throughout the day. Moreover, it's not restricted by external air hoses, allowing operators to move freely around the vehicle body—ideal for spraying parts like doors and hoods.

It's worth noting that selecting PAPR for automotive spraying also needs to take industry standards and practical details into account. PAPR is not an "optional equipment" for automotive spraying but a "must-have tool" to protect health and process quality. Choosing the right model and conducting proper maintenance can make spraying operations safer and more efficient. If you want know more , please click the www.newairsafety.com.

Read More